Multi-Scale Modeling of Multi-Phase Flows

Multi-Scale Modeling of Multi-Phase Flows

1.) Numerical simulations of gas-solid flows relevant to coal and/or biomass gasification: Lattice-Boltzmann simulations of unary and binary particulate flows, with a large number of particles, to understand the effects of particle size, shape and density on fluidization characteristics (flow regimes, bubbling characteristics, solid volume fraction, mixing and segregation characteristics) and their experimental validation using Time-Resolved Particle Image Velocimetry (TRPIV).

2.) Direct numerical simulations (DNS) of unary and binary particles with smaller number of particles to derive closure models for Eulerian (continuum) simulations.

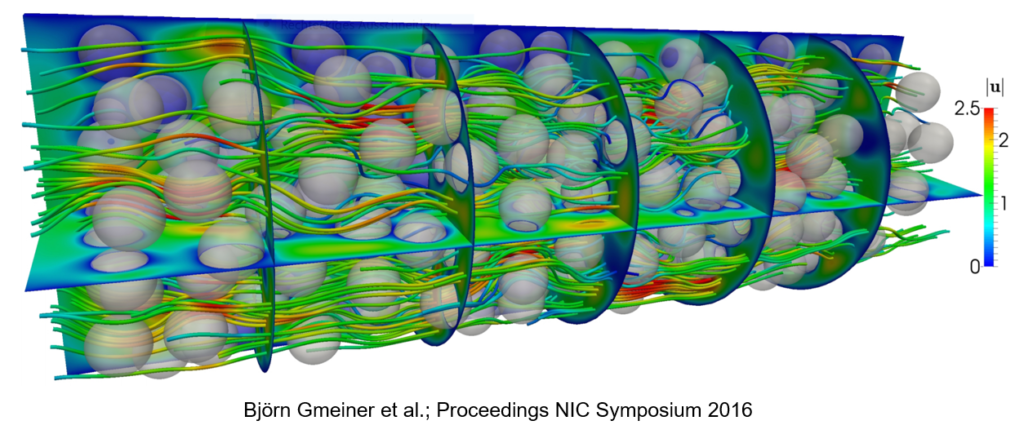

3.) Numerical simulations of gas-liquid through packed beds: Simulations of gasliquid two-phase flow through geometrically resolved packed beds and experimental validation using high-speed visualization imaging and Particle Image Velocimetry.

The availability of adequate, clean, and affordable energy is critical for realizing basic human needs and to further economic development. Modern society is heavily dependent on electricity, whether for industry or everyday communication. For now, energy systems are mainly dependent on fossil carbon, such as oil, gas, and coal. According to the 2018 International Energy Agency statistics, 42% of all energy related emissions are generated using coal. In Germany, proximately 35% of electricity was generated with coal in 2018 according to Statista. In India, it was 72% according to The Economic Times citing the Central Electricity Authority.

Any efforts in expanding energy availability are bound to increase the environmental impact by leaving a carbon footprint, water footprint, and impacting human health. Especially coal power plants are proven to have the highest negative impact on human health among the available electricity production processes. It is essential to make every effort to reduce the environmental footprint of energy systems and develop more efficient energy generation technologies that are also cleaner.

In the conventional pulverized coal (PC) based power plants, coal combustion is used to generate steam and then electricity. In contrast, in coal gasification based systems, the coal is converted into syngas (mainly CO and H2) which can be easily cleaned and then converted into either electricity via the IGCC (Integrated Gasification Combined Cycle) route or into synthetic fuels, such as gasoline and diesel. Because of the local availability of biomass, it’s also desired to gasify the biomass or co-gasify it with coal for the local generation of electricity. There are several challenges in improving the performance of the coal combustion boilers and in the development of an IGCC based power generation process that uses coal or biomass. Most of the processes employ a type of fluidized bed. One of the most important challenges is the efficient design of fluidized bed gasifiers for the gasification of coal and biomass. In order to develop simulation tools that can be used for design, scale-up, and performance optimization of large-scale coal-fired boilers or gasifiers, it’s important to understand the fluidization behavior of binary particle mixtures with varying size, shape, and density.

In addition to coal-based energy, there are several important applications that involve gas-liquid flow through packed beds. For example, in the oil refining industry for trickle bed reactors used for the removal of sulfur from liquid fuels and gas-liquid absorption columns. In all such processes, it’s important to understand the surface wettability characteristics and how the local liquid distribution changes as a function of local porosity. It is therefore important to develop computational tools that can simulate gas-liquid flow in packed beds.

One objective of this project is to perform Lattice-Boltzmann simulations of unary and binary particulate flows with a large number of particles, to understand the effects of particle size, shape, and density on fluidization characteristics. These characteristics include flow regimes, bubbling characteristics, solid volume fraction, mixing characteristics, and segregation characteristics. The numerical results will be validated with high-speed visualization imaging experiments to characterize the fluidization behavior of unary and binary particles, and also to perform continuous phase velocity flow field measurements using Time-Resolved Particle Image Velocimetry (TR-PIV). Furthermore, direct numerical simulations (DNS) of unary and binary particles with a smaller number of particles will be carried out to derive the closure models for Eulerian continuum simulations. Additionally, simulations of gas-liquid two-phase flows will be performed through geometrically resolved packed beds and compared with high-speed visualization imaging and Particle Image Velocimetry experiments to characterize the flow of gas and liquid phases through small specimens of liquid filled packed beds.

The expected outcomes of this project are:

• Experimentally validated computational models to simulate unary and binary particulate flows.

• The development of closures for Eulerian models for the simulation of binary particles based on direct numerical simulations.

• A deeper understanding of particle interactions and the effects of particle properties on dynamic characteristics of fluidization, mixing, and segregation of binary particles.

• Analyzing the effects of particle size and shape, bed porosity and surface characteristics on local velocity flow fields and gas-liquid distribution.

see also: Resources